Since construction began, our ongoing documentation of building site activities has been on display in an informative wall newspaper located in the Archive of the Future showroom in Lichtenfels’ market square. We interview the experts behind the construction of the Archive of the Future, and walk readers through the challenges faced in creating this exceptional building.

Watch and listen here to issue #2 of Construction Site News:

Civil engineer Undine Fuchs is responsible the structural engineering aspects of the Archive of the Future. In this issue she talks about the building’s exterior, which has just been completed. She explains the special features of the steel structure and provides interesting details about its planning and implementation. Undine Fuchs' answers can be listened to here, accompanied by explanatory images and text.

1 ) Special features of the steel structure

The architect conceived the building to have an open and transparent effect. The boundaries between inside and out should mix and merge, making them altogether indistinct. Accordingly, the load-bearing segment of the structure was eased as much as possible into the background. Undine Fuchs’ choice of slender steel girders and ultra-reduced floor thicknesses have allowed aesthetics to become the primary focus.

2 ) Structural challenges

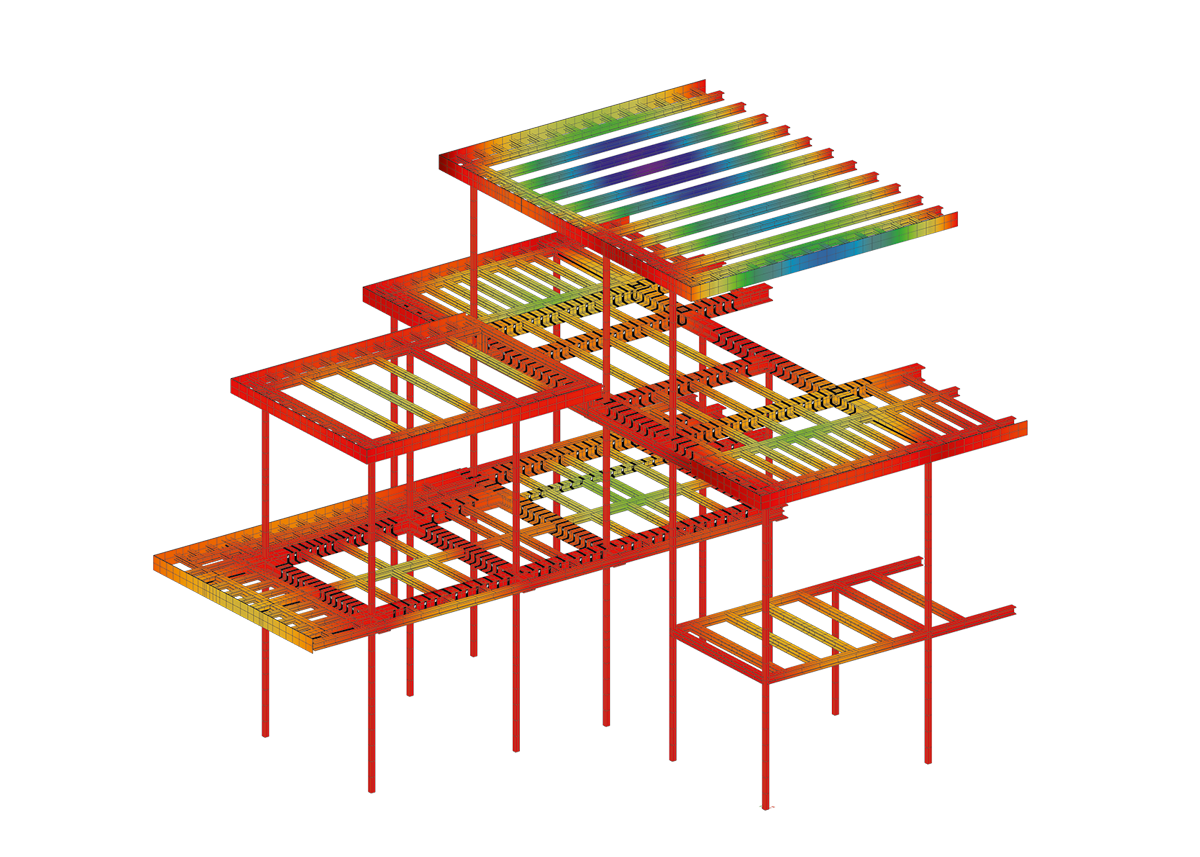

How can maximum stability be attained while using a minimal of materials? The stability strategy requires a thorough analysis of all forces that will later act on and in turn influence the design of the structure that will support them: the dead weight of the façade and roof; live loads, such as furniture and people; and environmental influences, such as wind and snow. Precise stress analysis and structural configuration are required, alongside a generous amount of computational support.

The image below details an indepth deformation analysis of the structure.

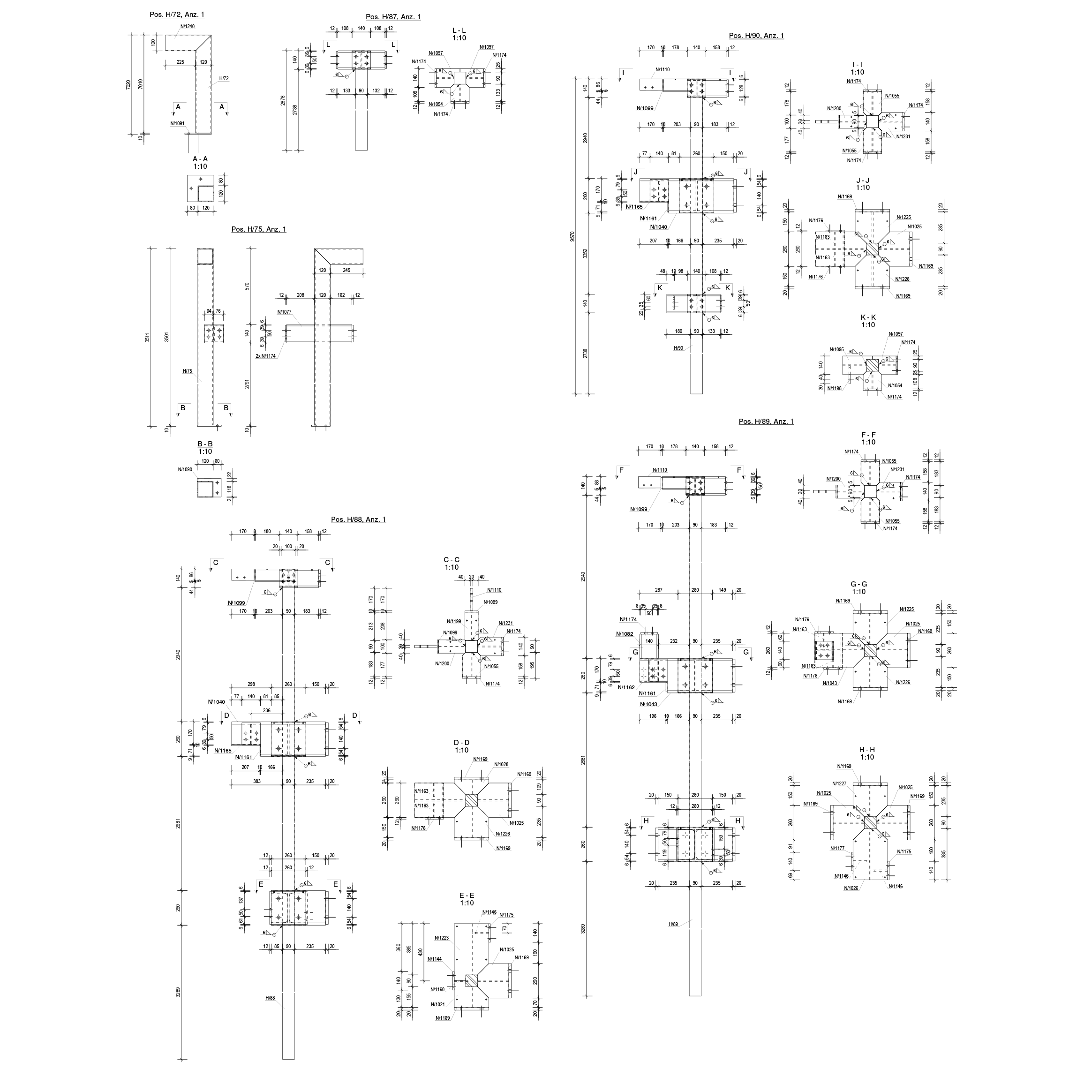

3 ) From planning to implementation

Months have been spent planning, and the individual parts of the steel structure have all been drawn down to the last detail. Every bead of weld, screw hole, and steel connection has been carefully scrutinized before being added to the construction manual for the workshop. The steel fabricators manufacture and deliver the building components while the construction crew assembles the structure on site. Finally Ms Fuchs is able to evaluate the physical results of her calculations. The image shows a section of a workshop drawing for a steel column.

4 ) Here’s how the project continues

During the next phase, the floor structures and building services will be installed and work will begin on the interior. The next major construction site activity will involve the mounting of the glass facade.

Helpful hint: In depth detail about other construction site challenges can be found in issue no. 2 of our magazine