Since construction began, our ongoing documentation of a number of building site activities has been on display in the Archiv’s showroom. The wall newspaper Construction Site News features several of the challenges faced by the many people involved in creating this exceptional building. We interview the experts and walk readers through a variety of compelling building-related issues.

You can watch and listen to the latest edition of our online Construction Site News here:

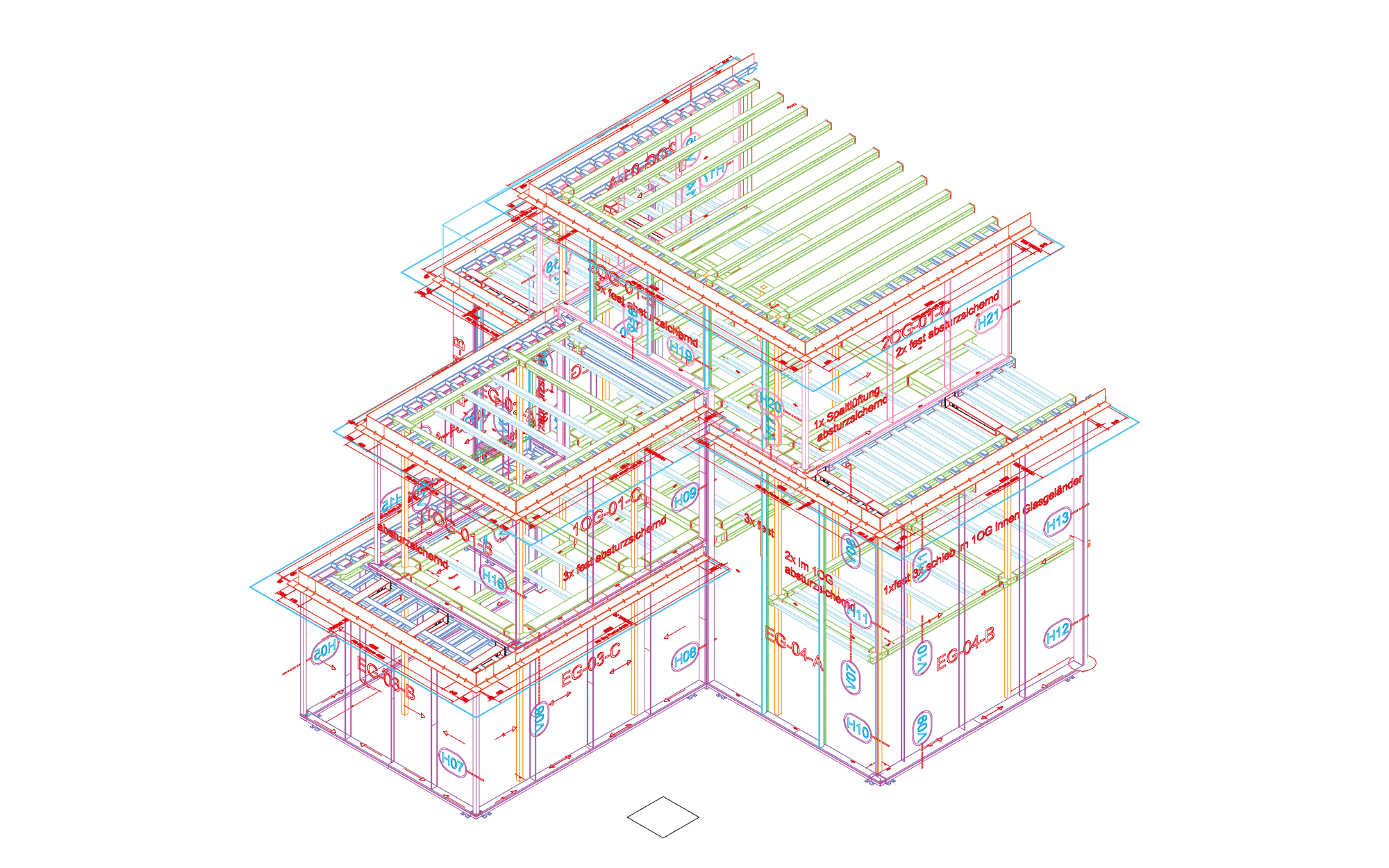

In this issue of Construction Site News, our focus shifts to the Archive of the Future’s remarkable glass façade. We spoke with metalworker Josef Gilch, who is responsible for the planning and installation of the Archive of the Future’s large-scale glass exterior. In our interview, Gilch delves into many of the pivotal details underlying this stage of construction.

A ) An exciting to-do list

The job given to us glass and metal workers revolved around the idea that the walls of this building should incorporate windows of the largest possible magnitude. The glass was to be virtually invisible, so that each floor would appear to almost hover in place. To achieve this we settled on using a minimal number of divisions, which led us to position the building’s metal struts as far apart as structurally possible.

B ) A well-conceived solution

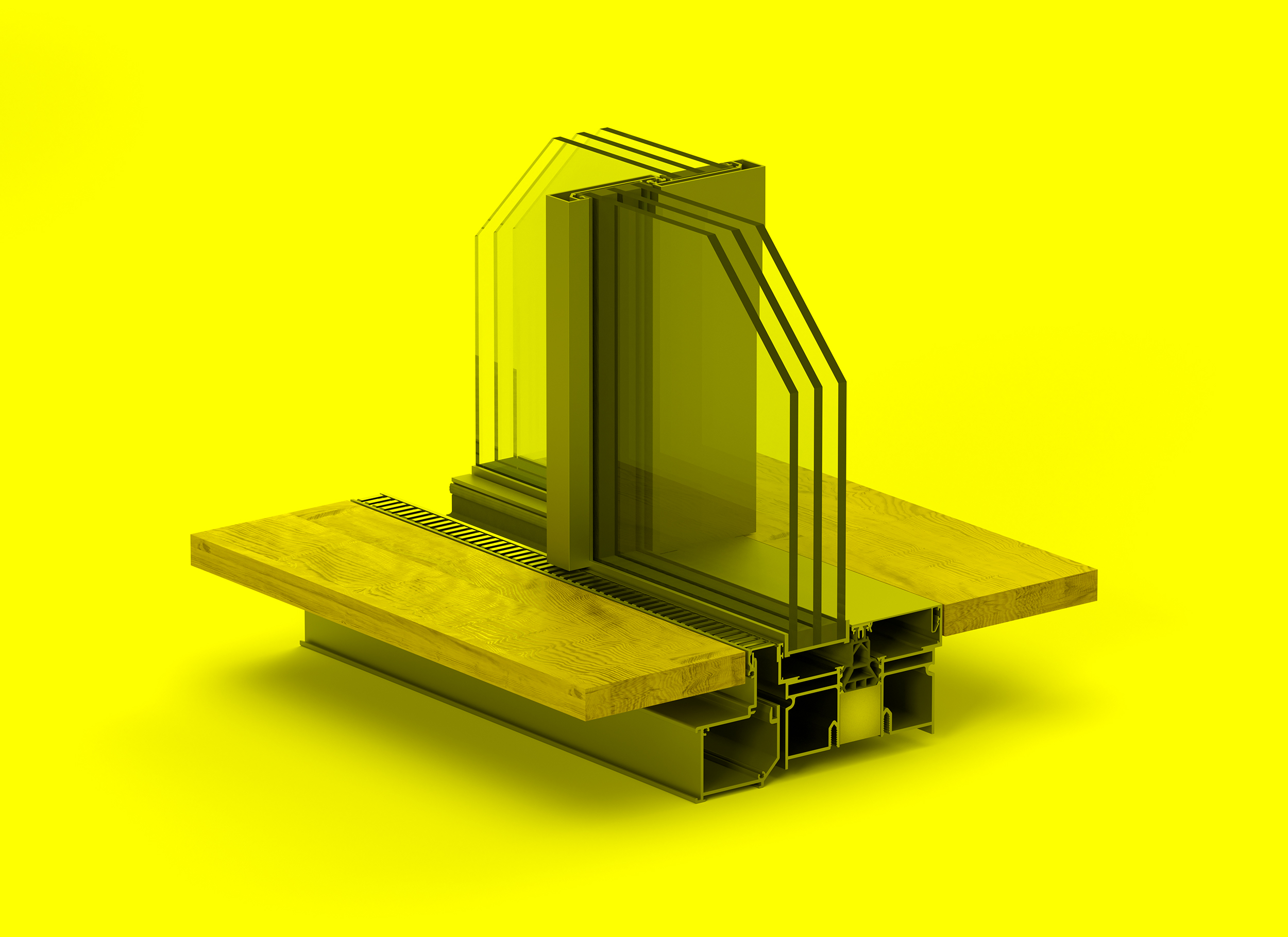

The walls of the building are made up of sliding windows six meters in height. The Swiss company Sky Frame, which manufactures modern, frameless windows in the Bauhaus tradition of Walter Gropius and Mies van der Rohe, signed on to produce them. The ultimate visual effect is one where interior and exterior spaces seamlessly merge.

C ) Protecting birds and harnessing energy

Large panes of glass often prove harmful to birds. They are easily confused by a window’s moving reflections, which can draw their flight into the glass. To minimize this phenomenon, we’ve selected highly anti-reflective panes – a measure that is prescribed by nature conservation authorities. A modern building envelope with good insulation ensures that very little heating energy seeps out during the winter months. In spite of their extensive surface area, the windows are composed of 3 glass panes, measuring 54 mm in thickness, making them energy efficient.This system of layered glass insulates on par with the conventional walls of a low-energy home.

D ) Delivery and installation

Windows six meters in height are by necessity delivered lying flat to the ground. These massive panes need to be installed on site using large vacuum lifting devices that employ suction to securely hoist them. Once in the grip of the device, they are then smoothly positioned and installed with the help of a tower crane. While the interior finishing work is next in line, plans for the manufacture and installation of the structurally ambitious and exacting willow architecture have simultaneously been in full swing.

Like to keep reading? A detailed article about further construction site challenges can be found in the third issue of our magazine.